CASE STUDIES

DEPUY ORTHOPEDICS

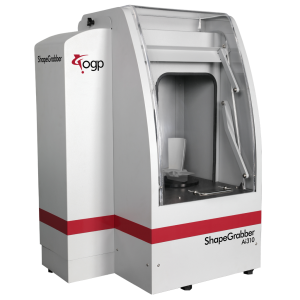

PROSTHETIC DEVICE MANUFACTURER RELIES ON SHAPEGRABBER FOR MEASUREMENT & INSPECTION

About The Company

DePuy Synthes is part of the Johnson & Johnson Family of Companies. They offer the world’s most comprehensive portfolio of orthopaedic and neuro products and services for joint reconstruction, trauma, spine, sports medicine, neuro, cranio-maxillofacial, power tools and biomaterials.

Founded in 1895, DePuy Orthopaedics was the first commercial orthopaedics company in the U.S. Our long standing commitment to innovation in patient care has helped us become a global leader in orthopaedic devices and supplies, including hip, knee, extremity, cement and operating room products. Today, the DePuy Synthes Joint Reconstruction portfolio includes more than 200 products.

Roger Erickson

DePuy Orthopaedics, a Johnson and Johnson subsidiary

THE CHALLENGE

DePuy Orthopaedics, Inc., a Johnson & Johnson company, designs, manufactures and distributes orthopaedic devices and supplies including hip, knee, extremity, trauma, orthobiologics and operating room products. Components like knee implants are checked with laser scanning, because of the complex sculptured contours required for proper functioning.

As DePuy developed more complex, sculpted medical device components, implants, and prosthetics, it found its measurement capabilities were limited by the low point density and relatively slow speed of traditional touch probe technologies.

Because its devices were being used by human patients, DePuy needed a dramatically higher density of point coverage to accurately capture the form and dimensions of these complex shapes, and the ability to compare them directly to CAD designs.

THE OGP SOLUTION

To obtain the high point density necessary for accurate measurements, DePuy selected a ShapeGrabber 3D laser scanning system. The ShapeGrabber solution proved to be faster and more versatile than other laser probe systems that DePuy evaluated, and the ShapeGrabber scanner was able to measure the complex, compound curves of DePuy parts quickly and accurately.

THE RESULT

Since choosing the ShapeGrabber system, DePuy has found that it can reconfigure the scanner quickly to accommodate parts of different sizes and can perform the quality assurance inspections it requires to ensure its low volume parts are properly formed and sized.

“For complete inspection of our anatomical implants, we opted for the touchless approach of laser scanning. Our first laser probe system was very slow and had limited function because it could only acquire one point at a time and could only measure diameters.”